I recently participated in an interview series on sales and operations planning (S&OP) with P.J. Jakovljevic from Technology Evaluations Centers (TEC). Similar to what we did with our own S&OP Expert Blog series (which PJ participated in), the Q&A really dives deep into key S&OP challenges and trends - so deep actually that I’ll be posting the article in a four-part series over the next four days. The entire Q&A along with PJ’s introduction and commentary on Kinaxis can be found here (free registration required).

Part One:

PJ: What do you believe is behind the surge of interest and activity around S&OP? What are the anticipated benefits?

TM: The surge of interest in S&OP is due to a combination of market drivers, available skills, and technology maturation. The primary market driver is a combination of mass customization/long tail and globalization of demand due to the recession in western economies and the increasing importance of the so-called BRIC (Brazil, Russia, India, China) countries as demand centers. This has led to a big increase in demand volatility, whereas outsourcing, on the other hand, has led to longer supply lead times and greater supply uncertainty. The combination of these factors means that brand owners are keen to regain control of their extended supply chains. There has been a simultaneous arrival of the Millennials (Generation Y) in the workforce, for whom the Internet and computers are natural tools for resolving competing and conflicting goals in a team-oriented fashion, as exemplified by their extensive use of Facebook and other social networks.

As S&OP is a multi-functional process by its very nature, it lends itself to the multi-enterprise nature of today’s supply chains, particularly in the high-tech/electronics vertical. Software tools are emerging that encourage and support the negotiation, compromise, and consensus building necessary in a multi-function, multi-tier process like S&OP through the use of scenario management and collaboration, including assumption capture. It is the Millennials’ experience with social networks, which are inherently collaborative, and the associated technologies that will drive both the adoption and the need for similar technologies in S&OP. The most obvious benefit is a more agile and aligned supply chain. How this will translate into hard benefits will depend on the current state of the company and the market in which it operates. In some cases, we are seeing that a good S&OP process is now ‘table stakes,’ required simply to keep up with competition. The benefits are principally those associated with supply chain efficiency—reduced inventory, improved capacity utilization, reduction in excess and obsolescence (E&O). Companies at the head of the pack are using S&OP to improve customer capture and retention through better demand sensing and supply chain agility to provide a profitable response to the market.

PJ: Do you think the definition of S&OP is clear in the marketplace? If not, is that a problem? How do you personally define S&OP?

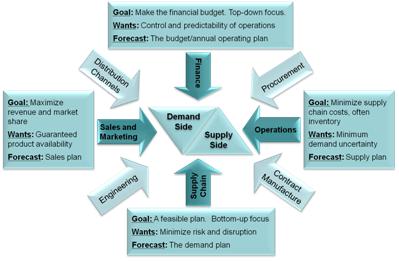

TM: The definition of S&OP is not clear, but I do not see that as a problem. I see the definition as evolving. S&OP was defined by Dick Ling nearly 30 years ago, and well before the advent of fax machines, PCs, spreadsheets, and the Internet—let alone laptops, iPads, and smartphones. I would be extremely disappointed if our definition of S&OP had not changed over that time. Tom Wallace has commented that an S&OP can be considered a success when there is cross-functional collaboration. I would agree that this is a necessary but insufficient definition of success. However, Tom is absolutely correct to highlight the importance of cross-functional collaboration due to the importance of reaching consensus despite competing goals and measures (figure 1). In today’s outsourced supply chains, collaboration must include at least the contract manufacturers. But with the ever-shortening product life cycles, how can the engineering/research and development (R&D) departments be excluded from S&OP? With life cycles of cell phones reduced to six months or less, running a monthly S&OP cycle focused on a 6−18 month horizon seems pretty pointless.

Figure 1. S&OP—Balancing Competing Goals

S&OP is the process that translates corporate business objectives, which are largely captured in the business planning or budgeting process, into feasible tactical plans that can be executed at the plant or supply chain level. The time horizon and granularity level at which S&OP is carried out will depend on the industry and market. We have some customers that plan as far as 5 years out, whereas others plan only 18 months out, as their product development horizon does not extend much beyond that. I do not believe that a ‘one size fits all’ approach when it comes to the S&OP process. Instead, I believe that some characteristics define how well S&OP is being carried out or the level of maturity of the S&OP process. Larry Lapide, research affiliate at MIT Center for Transportation and Logistics, captured these characteristics very well in a three-part series in the Journal of Business Forecasting, the last part of which was published in spring 2005, in which he describes the most mature level of S&OP as having the following: Event-driven meetings

- scheduled when someone wants to consider a change or when a supply-demand imbalance is detected

Extended processes

- demand and supply plans aligned internally and externally

- external collaboration with most suppliers and customers

Full set of integrated technologies

- an advanced S&OP workbench

- external-facing collaborative software integrated to internal demand-supply planning systems

Will be posted tomorrow. Stay tuned!

Additional Resources

- S&OP frequently asked questions

Leave a Reply