“Chief Supply Chain Officers (CSCO) know that there is no such thing as a perfect plan and disruptions will always occur.”

This is the reality that every member of a supply chain team lives with every day. And while sometimes, a disruption might be small and easily offset, some disruptions are more significant and have a greater impact on the supply chain before they can be resolved. Aberdeen Group’s recent research report – The Chief Supply Chain Officer’s View of Supply Chain Disruptions: How the Best-in-Class Respond – takes a look at this reality and what leading companies are doing to prepare for these unexpected events. So how does Aberdeen define Best-in-Class? Based on a survey of 151 end-user organizations, Aberdeen used the following metrics to identify the top 20%:

- 97% average customer service level (84% for All Others)

- 30 day average cash conversion cycle (59 days for All Others)

- 12% total logistics cost as a percentage of revenue (25% for All Others)

- 85% average forecast accuracy at the product family level

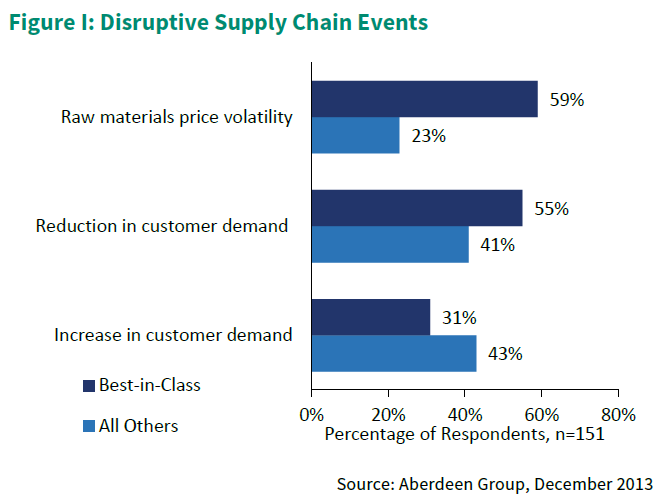

Regardless of where an organization falls on Aberdeen’s scale of maturity, none are immune to the disruptive forces impacting supply chains around the world. How an organization prepares for and addresses disruptions when they do occur is what sets the Best-in-Class apart. Figure 1 shows not only the top disruptions for the 12 months preceding Aberdeen’s research, but also shows how concerned leading organizations are for each type of disruptive event.

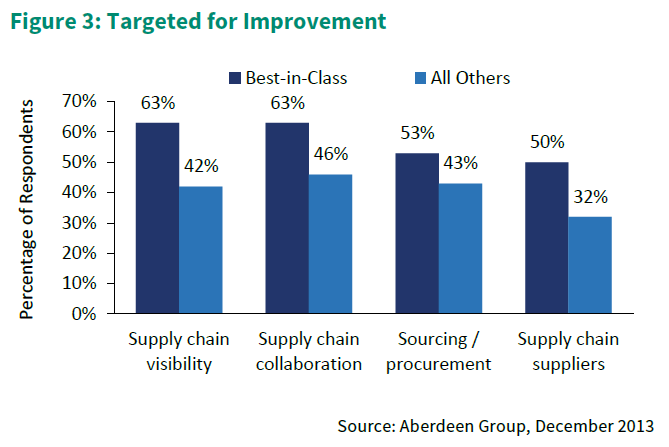

So what are Best-in-Class organizations doing to mitigate or plan for these disruptions? Aberdeen’s research highlights an “attitude of continuous improvement to constantly advance” as a distinguishing characteristic of those organizations identified as Best-in-Class. Two of the primary areas these organizations have targeted for improvement focus are supply chain visibility and supply chain collaboration. In fact, these Best-in-Class orgs are 50% more likely to focus on supply chain visibility and 37% more likely to focus on supplier collaboration than other organizations.

Discussions

You cannot prepare for every kind of disruption or disaster. But a best-in-class company knows how to prepare so that no matter what happens, they have a contingency plan in place. The best plans have enough guidelines so people know what to do, but are flexible enough to handle whatever curve balls come their way.

Leave a Reply