I came across a great blog post by Atul Chandra Pandey from Infosys titled “Y2010 & Ahead – value chain trends in emerging economy” in which Atul emphasized the following trends in the first part of a 2-part series:

- Customer side equations will take prominence over rest of value chain

- Supply chains will get more integrated with marketing and service chains

- Speed and responsiveness will be key drivers for spend on new initiatives

- Cost will continue to play critical role in decision making

- Asset Management will gain more prominence and will help in accelerating “green” initiatives

I responded to Atul in the following manner:

We too are experiencing that prospects and customers are focusing a lot more attention on customer satisfaction as it pertains to on-time delivery of orders, but also to the enquiry-to quote and quote-to-order processes. I couldn't agree more with your third point about speed and responsiveness. Overall the trend we are observing is that consumer behaviour is pervading B2B transactions with ever shorter lead times. Coupled with the adoption of Lean and postponement strategies, companies have to be very responsive to changing demand, blurring the lines between planning and execution. These are the business drivers for your third point about agility and responsiveness. Cost will always be a driver in supply chain management. If we adopt any of the Lean concepts it should be the elimination of waste. All too often I come across situations where the information and decision lead time exceeds the physical lead time to manufacture and/or deliver the order.

But this got me thinking about several other reports and observations that have come across my desk over the past 12 months. First and foremost must be the article by Dan Gilmore at Supply Chain Digest highlighting the work done by Supply Chain Digest’s research arm CSCO (Chief Supply Chain Officer) Insights. There is an excellent report titled ”Next Generation Supply Chain Management: Integrating Planning and Execution” available from this link. (Subscription required). In the article, Dan Gilmore observes that “For many years, analysts and others have offered separate models of ‘supply chain planning’ and ‘supply chain execution’ processes, and the technology vendors were generally organized in that sense as well.

You can find many diagrams that show hierarchical planning processes with no connection at all to execution, for example. The report argues, and the research supports, that this gap must be closed from a process perspective to meet the challenges of today’s supply chains.” I added the bolding because this is the key to being able to provide the speed and responsiveness to which Atul at Infosys refers. Not only that, but also managing to contain if not reduce supply chain costs will depend on being able to reduce this gap between planning and execution.

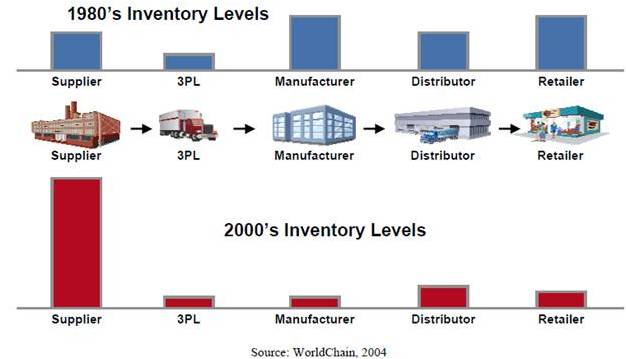

Traditionally we have used inventory to buffer against what we would like to happen (the plan) and what actually happens (execution). But this is no longer possible. As the graphic below illustrates, as long ago as 2004 postpone strategies had pushed much of the inventory up the supply chain to the suppliers. They too have adopted Lean and postponement strategies, leading to even lower inventories. And then there is the effect of the recent recession. Nearly all the OEM’s I speak to are struggling to secure supply of components, clearly indicating reduced inventory levels in the suppliers. I wish I had equivalent inventory figures for 2009. Anyone willing to provide these figures?

Then there is the excellent blog written by Lora Cecere recently titled “Tackling the Black Hole in the Center of Your Supply Chain” in which she states “We now know that fixed data integration, one-dimensional rules mapping, and traditional master data techniques from ERP to Supply Chain Optimization are insufficient. As a result, plans are created and consumed in isolation, and transactional systems hum along with little-- to no -- guided intelligence.” So as the speed of business has increased – some would describe this as volatility – the supply chain systems have not kept up. And most of the information is now external to your organization.

Companies have being trying desperately to get point-of-sale information to get early trend analysis of sales. At the same time, many brand owners have largely outsourced manufacturing, not only lengthening the physical supply of goods, but also the time and effort it takes to make a decision. All of these factors are only making the gaps between planning and execution even wider. But the business need is to close this gap; to respond to demand changes quickly and effectively.

As Lora Cecere, states, the solutions from the 1990’s have not kept pace with the business needs. Throwing more ERP at the problem isn’t the solution. At their heart, all ERP systems are essentially accounting packages. They deal with your data – financial and operational – but provide very little help in dealing with the majority of the information, which now exists outside of your organization.

What are your thoughts? Do you experience this gap? Are your systems able to cope. Will your next breakthrough in performance come from learning to plan better, or learning to respond to plan variance? In other words, closing this gap between planning and execution. Robust debate encouraged.

Leave a Reply